A Beginner’s Guide to Interlining

You know that feeling when you put on a perfectly tailored jacket? The shoulders hug you just right, the collar stays crisp all day, and the whole thing just looks sharp. It’s like wearing a suit of armor for your confidence! But have you ever wondered what gives a jacket that kind of structure? It’s not magic (although it sometimes feels that way), it’s all thanks to a hidden hero called interlining.

I recently got into sewing my own clothes, and let me tell you, it’s a humbling experience. I thought collars and cuffs were just, well, collars and cuffs. But then I learned about interlining, and it completely changed the game. It’s like adding a secret layer of support that takes your garments from floppy to fabulous.

So, today I wanted to demystify this whole interlining thing. It’s actually pretty simple, and once you understand it, you’ll appreciate the craftsmanship that goes into your favorite well-made pieces.

Table of Contents

- What is Interlining?

- Why Use Interlining?

- Where Do You Find Interlining?

- Types of interlining

- Sew-in / Non Fusible Interlining

- Fusible Interlining

- Fusible Interlining: A Breakdown by Resin

- Sew-in or Fusible?

What is Interlining?

Imagine a secret layer sandwiched between your garment’s main fabric and lining. That’s interlining! It’s a hidden gem that adds body, structure, and support to various parts of your clothes.

Why Use Interlining?

Interlining is a game-changer for garments in a few ways:

Sharpens Shapes: It helps collars, cuffs, waistbands, and other areas maintain their desired form.

Boosts Durability: By reinforcing specific areas, it prevents rips and tears during wear and tear.

Elevates Aesthetics: It creates a smooth, polished look and enhances the overall drape of the garment.

Improves Performance: It can add warmth, insulation, and even flame resistance in some cases.

Where Do You Find Interlining?

Interlining plays a key role in various garment components, including:

- Collars

- Cuffs

- Waistbands

- Plackets (openings for buttons or zippers)

- Facings (fabric layers that finish edges)

- Jackets and blazers

Types of interlining

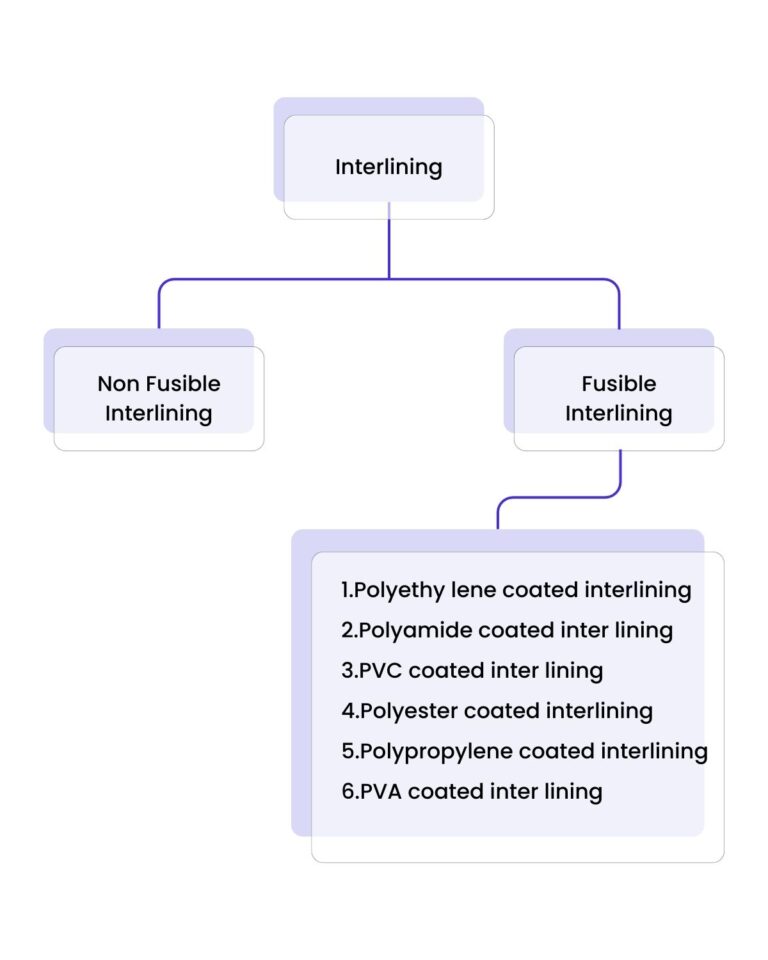

There are two main ways interlining gets attached to the fabric:

- Sewn (Non-Fusible): This method involves stitching the interlining to the main fabric. It’s often used for specific applications like flame-retardant garments.

- Fusible: This is the most common method. Fusible interlining has a heat-activated resin coating that bonds to the fabric with heat and pressure. It’s faster, easier, and offers a wider variety of options.

Sew-in / Non Fusible Interlining

Think of a tailor meticulously stitching an extra layer of fabric between your jacket’s main material and the lining. That’s Non fusible interlining in action!

The Process: Starch stiffens the interlining before it’s sewn onto the fabric.

Best for: Special needs like flame-resistant firefighter jackets or heavy-duty workwear. It’s also sometimes used in embroidery.

Pros: Simple, doesn’t require fancy tools, perfect for unique projects or repairs.

Cons: Time-consuming, less consistent quality than fusible, and finding materials might be tricky.

Fusible Interlining

Fusible interlining is the go-to interlining for most garments today. Here’s why it’s so popular:

The Process: Fusible interlining has a heat-activated resin coating on one side. Ironing it with pressure bonds it to the fabric.

Benefits: Creates a smooth, professional finish that elevates the look of your clothes. It also reinforces areas like collars and cuffs, keeping them sharp.

Fast & Easy: Compared to sew-in, fusible interlining is a breeze, perfect for home sewing and mass production.

Heads Up: Be careful with the heat! Always test a scrap of fabric first to avoid scorching.

Fusible Interlining: A Breakdown by Resin:

Fusible interlining comes in various flavors, each with its own properties based on the resin coating:

Polyethylene: Great for collars and cuffs of shirts, offering good dry cleaning resistance and washability.

Polyamide: Ideal for dry-cleanable garments that can withstand higher wash temperatures.

PVC: A versatile option for both dry cleanable and washable garments, commonly used in coats.

Polyester: The all-rounder, suitable for most garments, offering excellent performance but at a slightly higher cost.

Polypropylene: Similar to polyethylene but requires higher fusing temperatures and is washable.

PVA: Limited use in garments due to its poor dry cleanability and washability.

Link of related Articles

Shweta, a textile designer with a keen eye and deep knowledge of fabrics, translates her passion into unique designs. She loves to share her expertise and ignite a love for textiles in others. Dive into the world of fabrics with Shweta!