How Lightweight Interlining Enhances Woven Fabrics | Boost Performance

Have you ever wondered how your favorite garments maintain their shape and feel so comfortable? In this article, You will go through how lightweight interlining enhances woven fabrics and why it’s a game-changer for both designers and consumers. Whether you’re a fashion enthusiast, a textile professional, or simply curious, I’ll break it all down for you.

Table of Contents

- What Is Lightweight Interlining?

- Types of Lightweight Interlining

- Benefits of Lightweight Interlining

- Applications of Lightweight Interlining

- How to Choose the Right Lightweight Interlining

- Tips for Using Lightweight Interlining Effectively

- Conclusion

What Is Lightweight Interlining?

Lightweight interlining is a type of interlining fabric used between the outer fabric and the lining of a garment. It’s designed to provide additional structure, support, and performance benefits to the final product. Unlike traditional interlinings, lightweight interlining is made from materials that are both thin and flexible, ensuring that it doesn’t add unnecessary bulk to the garment.

Key Features:

- Thin and Flexible: Designed to maintain the fabric’s drape and movement.

- Breathable: Allows for better air circulation within the garment.

- Adhesive Properties: Often bonded to the outer fabric using heat or adhesive, such as fusible interlining.

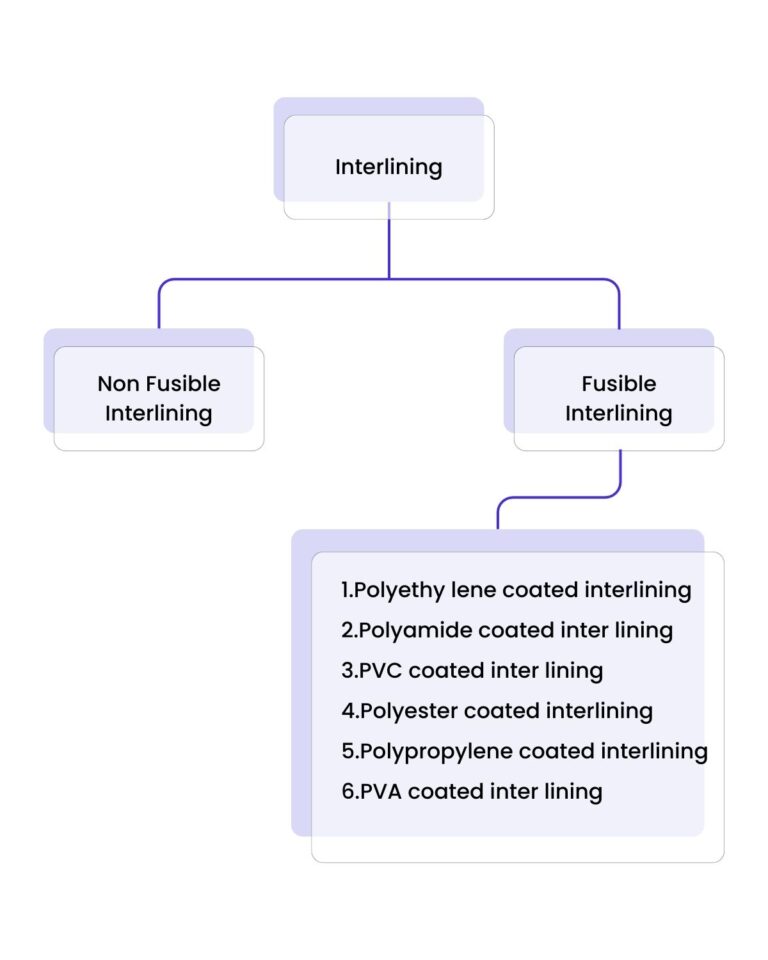

Types of Lightweight Interlining

There are several types of lightweight interlining available, each with its own unique properties:

- Fusible Interlining: This type of interlining fabric is bonded to the fabric using heat, making it easy to apply.

- Non-Woven Interlining: Non-Woven Interlining is made from fibers that are bonded together mechanically, making it lightweight and breathable.

- Woven Interlining: Woven Interlining is made from woven threads, providing a more structured and supportive base.

Benefits of Lightweight Interlining

Understanding the benefits of lightweight interlining can help you appreciate its role in enhancing woven fabrics. Here’s how it boosts performance:

Enhances Fabric Structure

Lightweight interlining provides a subtle structure to woven fabrics without compromising their natural drape. This added structure helps garments retain their shape, ensuring they look crisp and well-finished. You’ll notice this in tailored suits, dresses, and even home furnishings where a sleek appearance is desired.

How It Works:

Stiffness and Shape: Adds just the right amount of firmness, similar to the effects of woven interlining fabric.

Consistent Appearance: Prevents sagging or stretching.

Increases Durability

One of the major benefits of lightweight interlining is its ability to increase the durability of woven fabrics. By reinforcing the fabric, it helps prevent wear and tear, extending the life of your garments and textiles. This is especially important for high-use items like jackets and upholstery.

Durability Features:

Resistance to Fraying: Helps prevent edge fraying, especially in woven interlining fabric.

Enhanced Longevity: Reduces overall wear on the outer fabric.

Improves Comfort.

Even though lightweight interlining fabric adds structure, it does so without sacrificing comfort. The materials used are often designed to be soft and pliable, ensuring that the garment remains comfortable for extended wear. This balance of support and comfort is crucial for garments worn close to the skin.

Comfort Aspects:

- Soft Touch: Feels gentle against the skin.

- Breathable: Allows for better air circulation.

Applications of Lightweight Interlining

Lightweight interlining fabric is versatile and finds applications in various sectors. Here’s where it shines:

Fashion and Apparel

In the fashion industry, interlining fabric is essential for creating garments with a polished look. Designers use it to enhance the structure of blazers, coats, and formalwear. It’s also used in collars, cuffs, and waistbands to ensure they stay in place and look sharp.

Fashion Benefits:

- Tailored Fit: Provides structure without bulk, much like the effect of fusible interlining.

- Professional Finish: Enhances overall garment appearance.

Home Furnishings

In home furnishings, lightweight interlining is used to give drapes, blinds, and cushions a more refined finish. It helps maintain the shape of curtains and provides a smoother drape, enhancing the overall aesthetic of your home.

Home Benefits:

- Improved Drape: Ensures curtains hang beautifully.

- Enhanced Longevity: Helps furnishings last longer.

Technical Textiles

Technical textiles, such as those used in outdoor gear and sportswear, also benefit from lightweight interlining fabric . It adds performance features like water resistance and windproofing without compromising flexibility or comfort.

Technical Benefits:

- Enhanced Performance: Adds functional benefits similar to fusing interlining.

- Flexible Use: Maintains ease of movement.

How to Choose the Right Lightweight Interlining

Selecting the right lightweight interlining can make a significant difference in the performance of your woven fabrics. Here’s what you should consider:

- Material Compatibility: Ensure the interlining fabric is compatible with the outer fabric. Different fabrics may require specific types of interlining for optimal performance, such as non woven interlining or woven interlining.

- Adhesive Type: Choose between fusible (heat-activated) and sew-in types based on your project needs.

- Thickness and Flexibility: Select a thickness that provides the desired level of structure without adding bulk.

Tips for Using Lightweight Interlining Effectively

- Choose the right weight: The weight of the interlining should match the weight of the woven fabric.

- Cut the interlining to size: Make sure the interlining is the same size as the woven fabric.

- Apply the interlining correctly: Follow the manufacturer’s instructions for applying the interlining fabric .

- Test the interlining first: Before using a new type of interlining, test it on a scrap piece of fabric to make sure it’s compatible with your woven fabric.

Conclusion

Lightweight interlining fabric is a powerful tool in the world of textiles, enhancing the performance of woven fabrics in ways that you might not immediately notice but will appreciate in the finished product. Whether you’re working in fashion, home décor, or technical textiles, understanding and utilizing lightweight interlining fabric can elevate the quality and durability of your fabrics. I hope this guide has helped you see the value of lightweight interlining fabric and how it can make a difference in your projects.

Link of related Articles

- Woven Interlining for Men’s Shirts & Suits | Enhance Garment Structure

- Which is Better: Woven Interlining or Non-Woven Interlining

- The Role of Woven Interlining in High-Quality Tailoring | Key Benefits & Types