When you hear the term, “Interlining Fabric” you might be confused about what exactly it would mean. Let’s understand in simpler terms, Interlinings are the accessories used between two layers of fabric to keep the different components of apparel in the desired shape or to improve the aesthetics and/or performance.

Now let’s understand What is Fusible Interlining Fabric.

The concept of transforming the old cloth into new is something that we all have heard of, similarly, Fusible Interlining is used in a lot of garments and curtains as well.

What is Non-Fusible Interlining

Non-fusible interlining is an extra layer embedded between the outer fabric and the regular lining of a garment without chemical bonding.

These followings are the primary target of utilizing interlining in garments –

- Interlinings are primarily utilized for giving quality, security, and shape maintenance.

- At the period when melded to the external shell fabric, it goes about as a composite. Thus levels out the outer case against any distortion under load

- Improves pure and hand feel of fused laminate

- Contains the state of the united part throughout use and aftercare treatment

- Improves the life span of the melded part

Different Types of Fusible Interlining.

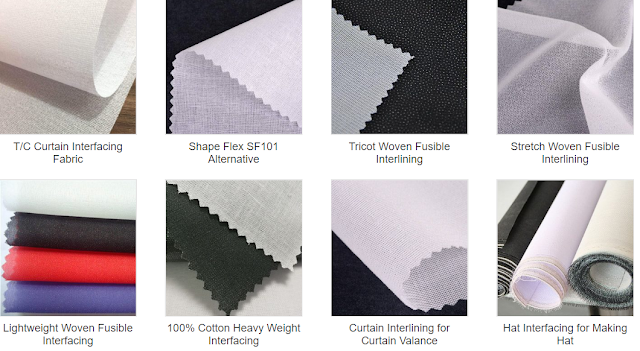

- Woven Interlining

- Non-Woven Fusible Interlining

- Waterproof Fusible Interlining

- Decorative Fusible Interlining

- Double-side Fusible Interlining

- Woven interlining

It was mainly 100% cotton fabrics made stiff by starch application and was non-fusible. However, the unpleasant hard touch and irregular points during washing led to the development of woven fusible interlinings. It is most often used by designers to avoid wastage.

- Non-woven Fusible Interlining

As the name suggests it is a non-woven interlining but more like sheets of paper or cardboard. This type of material is used for bags and purses.

It is made directly from fiber to fabric stage in the process reducing the cost of the base fabric. As there is no yarn used in producing nonwovens, it lacks the strength needed for garment use and there are many methods applied to present required power to non-woven textiles, called Bonding.

- Waterproof Fusible Interlining

As the name suggests the material used is waterproof and the material made from it can easily be water-resistant.

- Decorative Fusible Interlining

This is often used for adding badges, patches, and can also be used to discreetly hide a hole while making your wardrobe more stylish

.

- Double-sided Fusible Interlining

Double-sided fusible interlining is used to get rid of holes in clothing, especially jeans.

It’s very easy to use as both sides of the material can be used in this method.

How Do You Use Fusible Interlining Fabric?

Fusible Interlining is very smooth to use as long as you choose the right type. Now let’s understand how to apply in by the following steps,

- The first step is to mark out from the size that you want leaving out some extra space if you are repairing any hole.

- Mark the area that you need and place the fusible interlining wherever you want it.

- The fusible interlining would act as a glue right here. Use a heated object or an iron to make the glue melt, so that the interlining sticks to the fabric.

- Place your iron on each part for 30-40seconds before any movement.

- Leave it for sometimes all the fabric has got stuck in the right way. To avoid glue on the iron board make sure you place cotton underneath.

Post Credit –