Importance of Fusible Interlining for Structured Collars | Enhance Garment Quality

If you’ve ever admired a perfectly crisp collar on a shirt or jacket, you might be wondering what makes it stand out. The secret often lies in fusible interlining. In this article, I’ll explain why fusible interlining is crucial for creating structured collars and how it enhances the overall quality of garments. Whether you’re a fashion designer, a DIY enthusiast, or just someone interested in garment construction, you’ll find this guide useful.

Table of Contents

- What Is Fusible Interlining?

- Why Fusible Interlining Matters for Structured Collars

- How Fusible Interlining Works

- Choosing the Right Fusible Interlining

- Tips for Using Fusible Interlining Effectively

- Conclusion

What Is Fusible Interlining?

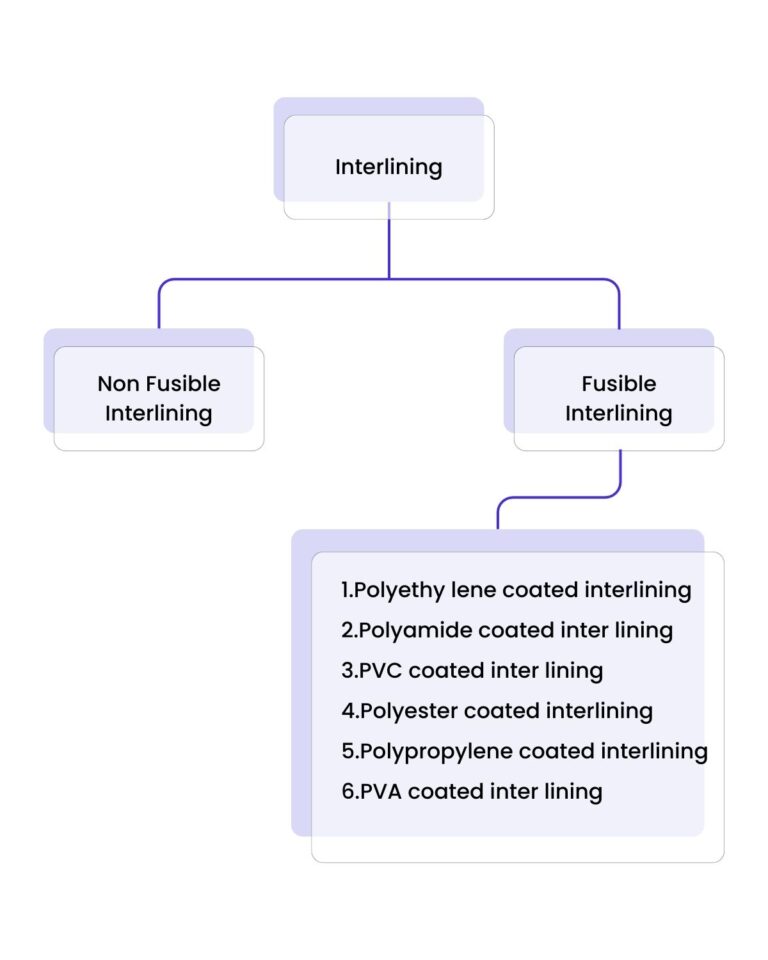

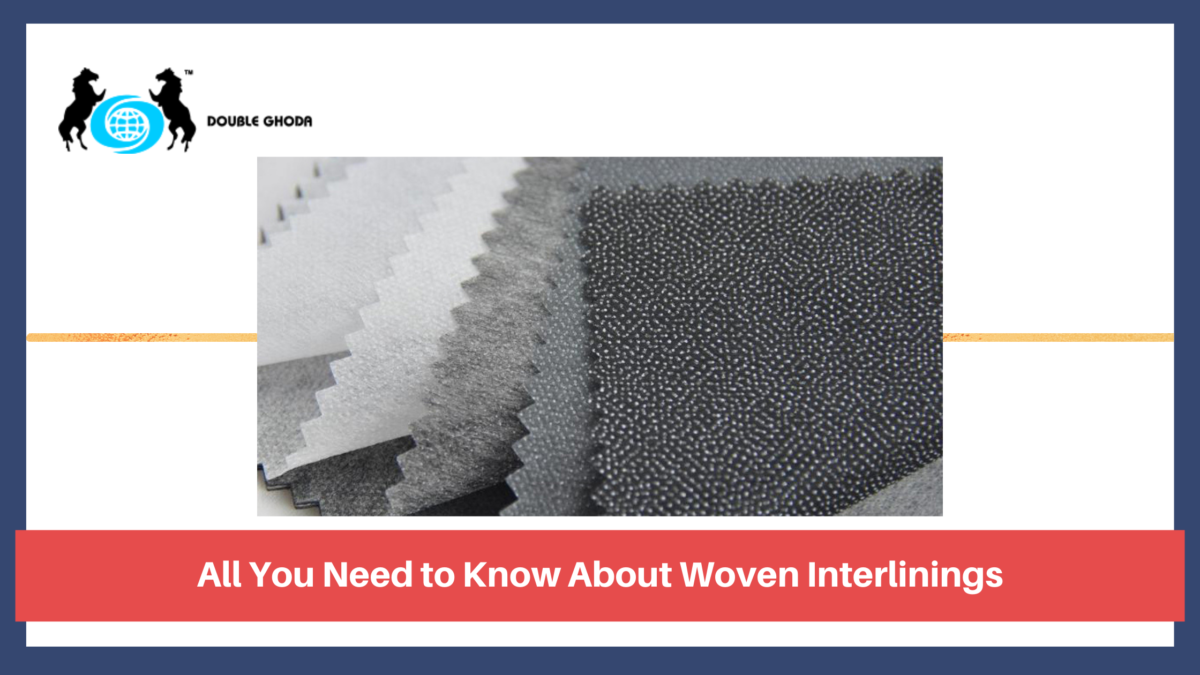

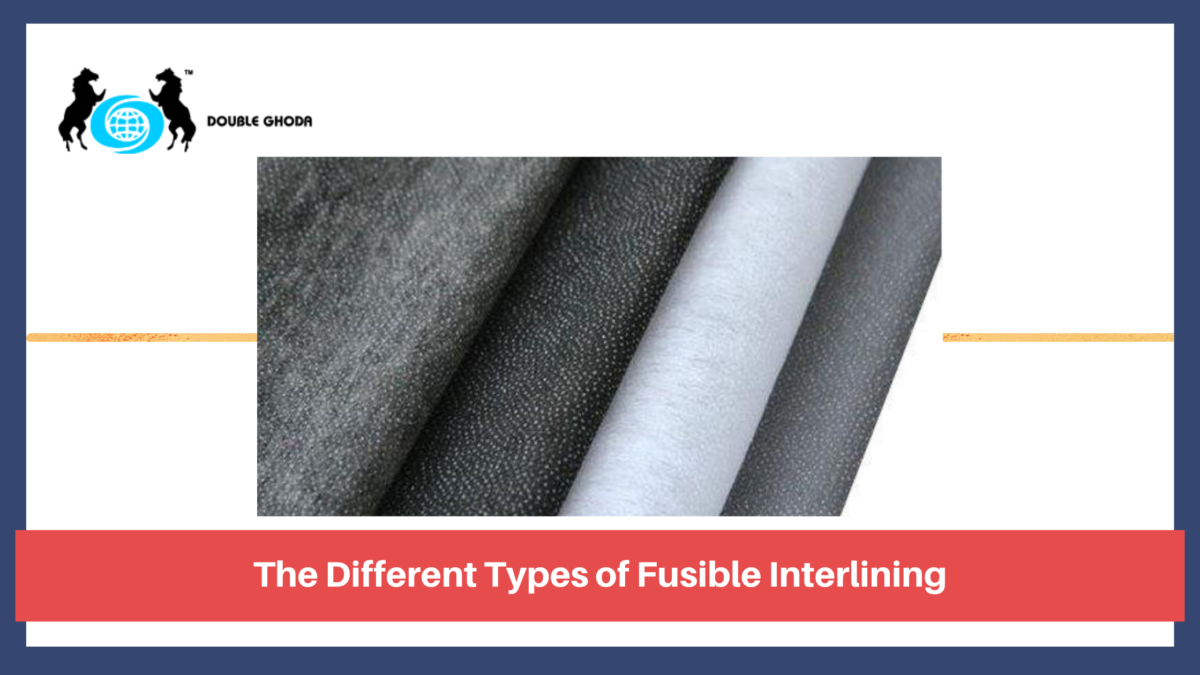

Fusible interlining is a type of interlining fabric that is used to add structure and stability to garments. It is bonded to the outer fabric using heat, creating a permanent bond that provides firmness and shape. Unlike other interlinings, fusible interlining comes with an adhesive coating that activates when heated, making it easy to apply and ensuring a strong, lasting hold.

Key Features:

- Adhesive Coating: Activated by heat for a strong bond.

- Thin and Flexible: Adds structure without bulk.

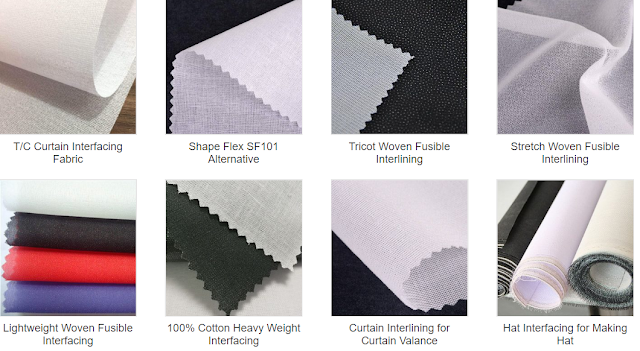

- Variety: Available in different weights and types, such as non woven interlining and woven interlining, to suit various fabrics and needs.

Why Fusible Interlining Matters for Structured Collars

Using fusible interlining is essential for creating well-defined, structured collars. Here’s why it’s so important:

Enhances Structure and Shape

Fusible interlining provides the necessary stiffness to collars, helping them maintain their shape and stay crisp throughout wear. It prevents collars from sagging or losing their form, ensuring a polished look. This effect is similar to what you achieve with woven interlining fabric.

Benefits:

- Firmness: Provides the right amount of stiffness for a sharp collar, akin to the effects of woven fusible interlining.

- Shape Retention: Maintains collar shape over time.

Increases Durability

By reinforcing the collar, fusible interlining also increases the overall durability of the garment. It helps prevent wear and tear, such as fraying or stretching, extending the lifespan of your clothing. This is especially true for lining and interlining fabric, which contributes to the garment’s longevity.

Durability Features:

- Resistance to Fraying: Helps edges stay intact, similar to the benefits of non-woven interlining.

- Enhanced Lifespan: Reduces the need for frequent repairs.

Improves Appearance

A well-structured collar enhances the appearance of any garment, giving it a professional and polished look. Fusible interlining ensures that collars lay flat and look crisp, contributing to the garment’s overall quality. This is crucial for garments that require a high level of finish, like those with fusing interlining.

Appearance Benefits:

- Professional Finish: Provides a clean, sharp look, much like woven interlining fabric.

- Consistent Quality: Ensures collars always look their best.

How Fusible Interlining Works

Understanding how fusible interlining works can help you appreciate its role in garment construction. Here’s a quick overview:

- Heat Activation: The adhesive coating on fusible interlining melts when heated, bonding it to the outer fabric.

- Bonding Process: The interlining is placed between the outer fabric and the collar lining. Heat is applied using an iron or pressing machine.

- Result: The interlining adheres firmly to the fabric, providing structure and stability. This process is similar to applying interlining fusible.

Application Tips:

Even Heat Distribution: Ensure that heat is evenly applied to avoid uneven bonding.

Proper Alignment: Align the interlining carefully to prevent misalignment of the collar.

Choosing the Right Fusible Interlining

Selecting the right fusible interlining is crucial for achieving the desired results. Consider these factors when choosing:

- Fabric Compatibility: Ensure that the interlining is suitable for the type of fabric you are using, whether it’s woven interlining or non woven fusible interlining.

- Weight and Thickness: Choose the appropriate weight and thickness based on the level of structure needed.

- Adhesive Strength: Opt for an adhesive that matches the durability requirements of your project.

Tips for Using Fusible Interlining Effectively

- Choose the right weight: The weight of the fusible interlining should match the weight of the fabric.

- Cut the fusible interlining to size: Make sure the fusible interlining is the same size as the collar.

- Apply the fusible interlining correctly: Follow the manufacturer’s instructions for applying the fusible interlining.

- Test the fusible interlining first: Before using a new type of fusible interlining, test it on a scrap piece of fabric to make sure it’s compatible with your fabric.

Conclusion

Fusible interlining plays a vital role in creating structured collars and enhancing the overall quality of garments. It adds the necessary stiffness and durability, ensuring that collars remain crisp and professional-looking. By understanding and using fusible interlining, you can significantly improve the appearance and lifespan of your clothing. I hope this guide has provided you with valuable insights into the importance of fusible interlining and its impact on your garment construction projects.

Link of related Articles

- The Ultimate Guide to Heavyweight Fusible Interlining: Everything You Need to Know

- Fusible vs. Sew-In Interlining: Which is Perfect for Your Sewing Project?

- Fusing Interlining on Delicate Fabrics: Tips and Tricks