Woven Interlining for Men’s Shirts & Suits | Enhance Garment Structure

When it comes to men’s fashion, the secret to a perfectly structured shirt or suit often lies in what you can’t see – the interlining. You may have noticed how some garments maintain their crispness and shape, even after hours of wear, while others tend to lose their form. The difference is woven interlining. This essential yet often overlooked component plays a crucial role in enhancing the structure, durability, and overall appearance of men’s shirts and suits.

In this article, I’ll guide you through the ins and outs of woven interlining, why it’s important in garment construction, and how choosing the right type can elevate your wardrobe to new heights. Whether you’re a fashion enthusiast, a designer, or simply someone who values a well-tailored look, understanding woven interlining fabric is key to achieving that polished, professional finish in your attire.

Table of Contents

- What is Woven Interlining?

- Why is Woven Interlining Important?

- Types of Woven Interlining

- Why Woven Interlining is Essential for Men’s Shirts & Suits

- Choosing the Right Woven Interlining

- Benefits of Using Woven Interlining

- Best Practices for Applying Woven Interlining

- Care Tips for Woven Interlining

What is Woven Interlining?

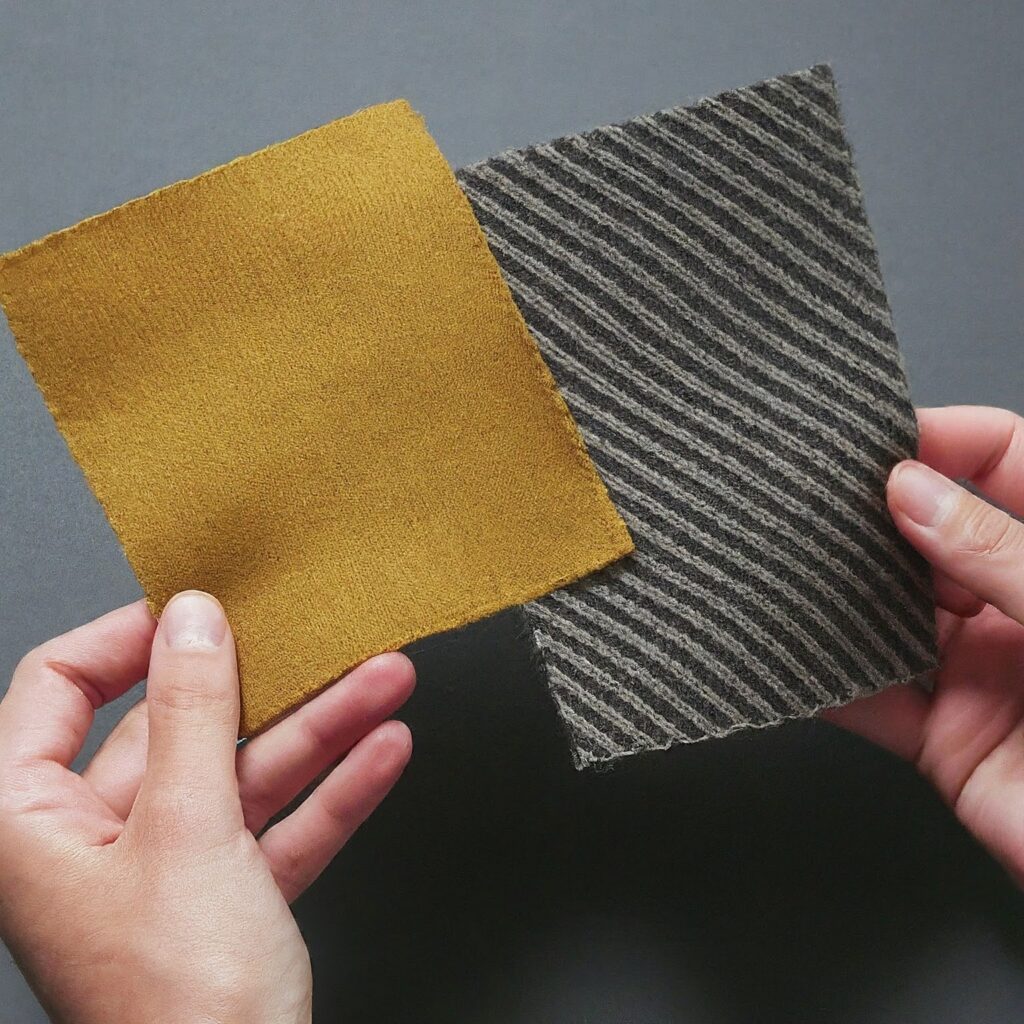

You might be wondering, what exactly is woven interlining? Well, woven interlining is a crucial component in fashion, especially when it comes to men’s shirts and suits. It’s a fabric layer inserted between the outer fabric and the inner lining of a garment. This fabric layer is made using a weaving technique, which gives it a sturdy yet flexible structure.

Woven interlining fabric enhances the shape, drape, and overall structure of your garments, ensuring they look polished and professional every time you wear them. While non-woven interlining offers certain advantages, woven interlining excels in providing superior support and durability due to its interlaced yarn construction.

Why is Woven Interlining Important?

You might be wondering why you should care about something you can’t see. Well, woven interlining is like the skeleton of your garment. It provides:

- Shape Retention: Prevents your shirt or suit from sagging or losing its form over time.

- Drape: Contributes to the elegant fall of the fabric.

- Comfort: Adds a layer of softness and warmth.

- Durability: Extends the life of your garment.

Types of Woven Interlining for Men’s Garments

Interlining types vary widely, each offering distinct properties. There are several types of woven interlining available, each offering different benefits depending on the garment and desired outcome. Here’s a quick breakdown:

- Lightweight Woven Interlining: Ideal for dress shirts where you want to maintain a soft and natural feel.

- Medium Weight Woven Interlining: Best for structured garments like suit jackets and blazers, offering a balance between flexibility and rigidity.

- Heavyweight Woven Interlining: Used in areas that require maximum structure, like collars and cuffs.

Choosing the right type of woven interlining can make all the difference in how your garment looks and feels.

Why Woven Interlining is Essential for Men’s Shirts & Suits

If you’ve ever worn a well-tailored shirt or suit, you’ve likely experienced the difference between woven interlining and non-woven interlining. Woven interlining is what makes the difference. Here’s why it’s so important:

- Enhanced Structure: Woven interlining helps your shirts and suits maintain their shape, even after multiple wears and washes.

- Improved Durability: It adds an extra layer of strength, making your garments last longer.

- Professional Appearance: This interlining fabric provides a crisp, clean look that’s essential for business attire.

Choosing the Right Woven Interlining

Selecting the appropriate interlining fabric is essential for achieving the desired garment outcome. Consider these factors:

- Garment Style: The desired shape and drape will influence the choice of interlining.

- Fabric Weight: The interlining should complement the weight of the outer fabric for optimal results.

- Climate: Consider the climate when selecting the weight and warmth of the interlining.

Benefits of Using Woven Interlining

Investing in high-quality woven interlining is a wise decision. It offers numerous advantages:

- Shape Retention: Woven interlining helps your garments hold their shape, so they always look sharp.

- Comfort: Despite adding structure, it doesn’t compromise on comfort. You’ll feel just as good as you look.

- Versatility: It’s suitable for a wide range of garments, from everyday shirts to high-end suits.

- Increased Lifespan: Garments with woven interlining fabric are more durable, meaning you get more wear out of each piece.

Best Practices for Applying Woven Interlining

Applying woven interlining might seem like a task best left to professionals, but if you’re a DIY enthusiast or simply curious, here are some best practices to follow:

- Pre-Shrink the Interlining: Always pre-shrink the woven interlining fabric before applying it to prevent any unwanted shrinking after the garment is made.

- Align with Grain Lines: Make sure the interlining fabric is aligned with the grain lines for a smooth, natural drape.

- Use a Press Cloth: When fusing the interlining fabric, use a press cloth to avoid direct heat contact, which can damage both the interlining and the garment fabric.

- Test on Scrap Fabric: Before applying it to the actual garment, test the interlining on a scrap piece of fabric to ensure it behaves as expected.

Care Tips for Woven Interlining

To preserve the quality of your garments, follow these care guidelines:

- Dry Cleaning: Most woven interlinings require professional dry cleaning.

- Avoid Heat: Excessive heat can damage the interlining fibers.

- Proper Storage: Store your garments on hangers to maintain their shape.

Conclusion

Woven interlining may not be visible on the outside, but its impact is undeniable. By enhancing the structure, durability, and appearance of your shirts and suits, woven interlining ensures that you always look your best, whether you’re at the office or at a formal event.

Link of related Articles

- Advantages and Disadvantages of Woven Interlining

- Non-Woven vs Woven Interfacing: Which is Best for Your Project?

- Choosing the Right Woven Interlining: Key Factors to Consider