Applications of Non-Woven Interlining in Fashion Industry | Key Insights

Non-woven interlining is a really important part of making clothes better in the fashion industry. Unlike woven interlining, non-woven interlining is made by bonding fibers together through various methods, including heat, pressure, or adhesives. This process creates a fabric that is both versatile and functional, making it a staple in modern garment construction.

Interlining fabric provides essential support and structure to garments, and non-woven interlining is particularly valued for its unique properties. Whether you’re working with fusible interlining or exploring different interlining types, understanding the differences between these options is crucial for achieving the best results in your fashion projects.

Table of Contents

- Understanding Non-Woven Interlining

- Benefits of Non-Woven Interlining in Fashion

- Key Applications in Garment Design

- Choosing the Right Non-Woven Interlining

- Future Trends in Non-Woven Interlining

- Conclusion

Understanding Non-Woven Interlining

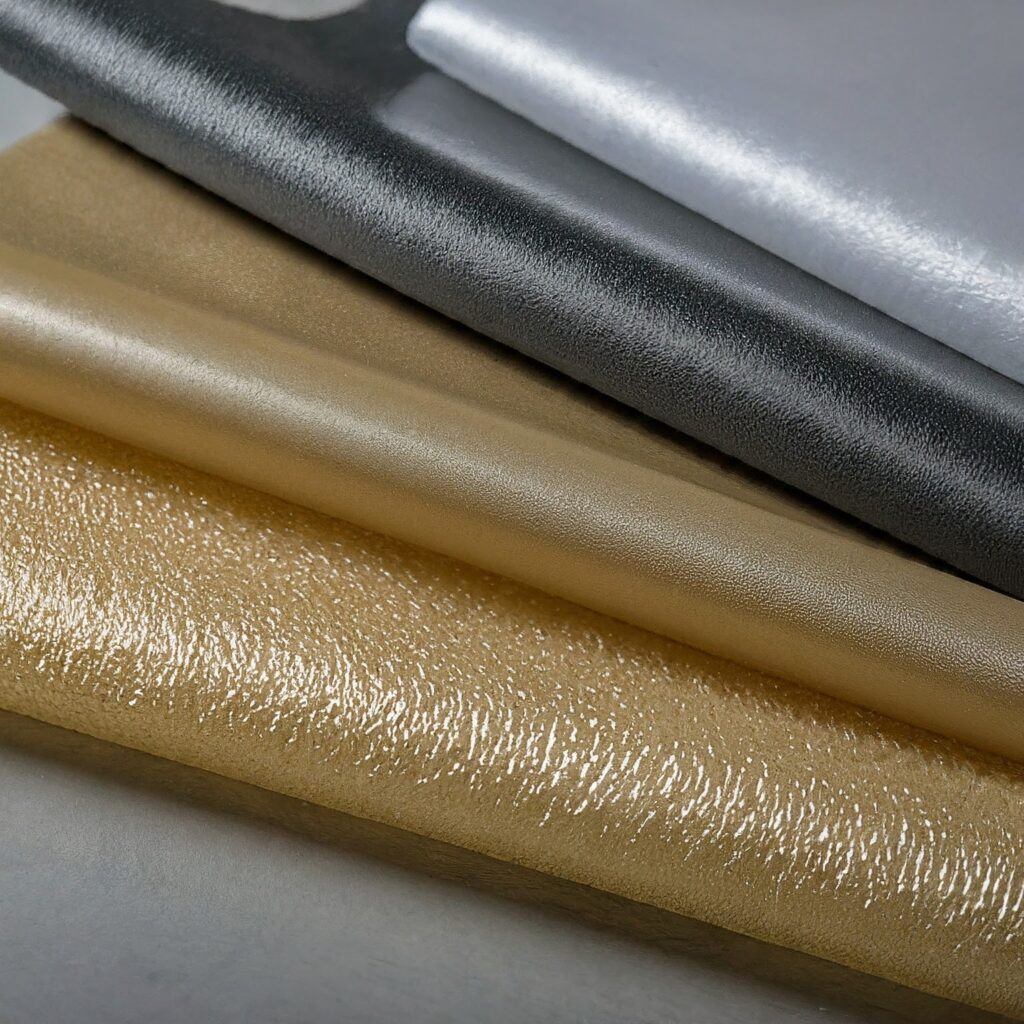

Non-woven interlining is a fabric made from fibers that are bonded together mechanically or chemically, rather than being woven or knitted. It’s characterized by its softness, flexibility, and breathability. Non-woven interlining is available in various weights, textures, and finishes, making it suitable for a wide range of garment applications.

Benefits of Non-Woven Interlining in Fashion

Non-woven interlining offers several benefits that can significantly impact the quality and durability of your garments:

- Enhanced Structure: Provides excellent support and shape retention, ensuring garments maintain their form and fit over time. This is particularly useful in applications such as suit jackets and collars, where woven interlining fabric might be less suitable.

- Improved Comfort: Adds softness and flexibility, making the garment more comfortable to wear. This is especially beneficial when using non-woven fusible interlining in designs requiring a softer touch.

- Versatility: Available in various weights and thicknesses, making it suitable for a wide range of applications. Whether you need woven fusible interlining or non-woven interlining, there’s a product that meets your specific needs.

- Cost-Effective: Generally less expensive than woven interlining, offering a budget-friendly option without compromising quality.

Key Applications in Garment Design

Non-woven interlining plays a crucial role in various aspects of garment design:

- Collars and Cuffs: Adds structure and crispness to collars and cuffs, ensuring they stay in place and look sharp. Using fusible interlining here can enhance the final appearance.

- Suit Jackets: Provides support and shape to the jacket, enhancing its overall fit and appearance. Choosing the right interlining in garments is key for achieving a professional look.

- Skirts and Dresses: Helps in creating a smooth and polished look by preventing the fabric from sagging or wrinkling. Non-woven interlining is particularly effective in this context.

- Pockets: Reinforces pocket areas, preventing wear and tear and maintaining their shape. Interlining fabric helps ensure that pockets retain their form over time.

Choosing the Right Non-Woven Interlining

Selecting the appropriate non-woven interlining for your project involves considering several factors:

- Fabric Weight: Choose a weight that matches the fabric of your garment to ensure proper support and comfort. For example, woven interlining fabric might be more suitable for heavier fabrics, while non-woven interlining can be ideal for lighter materials.

- Adhesive Type: Depending on your needs, select an interlining with the right adhesive properties for optimal bonding and performance. Interlining fusible options offer convenient heat bonding, while non-fusible varieties require stitching.

- Application Method: Some non-woven interlinings are fusible, meaning they can be bonded with heat, while others are non-fusible and require stitching. Consider how fusing interlining aligns with your garment construction needs.

Conclusion

Incorporating non-woven interlining into your garment designs can significantly enhance their quality and longevity. By understanding its benefits and applications, you can make informed choices that elevate your fashion creations. Whether you’re working with woven interlining fabric or exploring other interlining types, embracing non-woven interlining will help you achieve professional results and create garments that stand out.

Link of related Articles

- The Benefits of Non-Woven Interlining for Cuffs and Collars

- How Non-Woven Interlining Enhances Garment Durability and Quality

- The Future of Non-Woven Interlining: Innovations, Trends, and Applications