What is interlining?

Interlining is a layer of textile used between two outer layers of shell fabric to impart strength, support, stability and shape retention to the outer shell fabric against any distortion due to stress exerted at various stages of production, during wearing/use or aftercare treatments. The interlining is also called as interfacing.

Difference between interlining and lining

The lining is a layer of textile used under the garment as cover to the raw edges and smooth surface to support outer shell for good drape. It can be woven or knits as needed for a particular application/use. For an example, in the girl’s frock, you will find white lining fabrics under the shell fabric.

As said above interlining is used between two outer fabric layers. For an example, fusible interlining used in collar and cuff in men’s formal shirts for stiffening the said components.

Why use interlining?

Followings are the primary objective of using interlining in garments.

- Interlinings are primarily used for imparting strength/support, stability and shape retention.

- When fused to the outer shell fabric it acts as a composite and stabilizes the outer shell against any distortion under stress

- Helps improve aesthetic and hand feel of fused laminate

- Helps retain the shape of the fused part during use and after care treatment

- Improves longevity of fused part

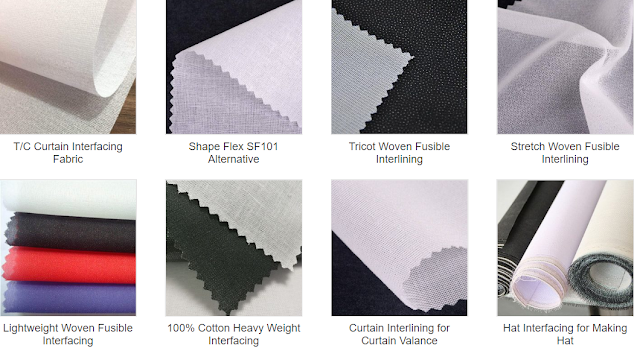

Different types of interlining available/in use

Interlining can be classified into different types based on:

a) Based on the base fabric structure interlinings are categorized into 3 types

- woven interlining,

- knits interlining and

- nonwoven interlining

b) Based on its application point, interlinings are categorized as

- non-fusible or

- fusible

#1. Woven interlining

Primarily woven interlinings were first used 100 years ago to strengthen/support coats, cloaks and gowns or hat. It was mainly 100% cotton fabrics made stiff by starch application and was non-fusible. However, the unpleasant hard touch and irregular characteristics during washing led to the development of fusible interlinings.

Normal cotton sheeting fabrics were applied with a layer of adhesive that can be fixed to the shell fabric by application of heat or pressure. This formed a composite part of the fused shell part and supported the outer shell for better drape and look.

Woven interlinings are majorly 100% cotton based with a thread density of variable count as required for the weight or stiffness needed for a particular use. Now poly-cotton blends are also available to overcome the problems of shrinkage faced in cotton fabrics together with a variety of warp and weft combination like rayon, texturized poly and wool etc.

Advantages of woven interlining

The main advantage of woven fabrics is its strength and stability, hence used for all such applications where strength and stability are needed like the waistband.

However, this could be a disadvantage at times where flexibility and soft hand feel is required.

Woven is majorly plain weaves, sometimes crepe, herringbone or twill weaves are also offered according to the application need.

In such cases, texturized poly yarns are used for voluminous body, soft and natural hand feel or drape of the fused composite at the same time strength, flexibility and lightweight of the fused laminate is achieved without much altering the natural drape or texture of shell fabric.

However, woven is expensive and not suitable for less expensive casual garments hence, it was replaced by knitted fabrics that used a combination of synthetic yarns with rayon and wool for body and volume according to different application intended for.

#2. Knitted interlinings

The major disadvantage of woven in its flexibility, lightweight and soft handle was duly addressed by knitted fabrics. Knitted fabrics have a large number of variation in terms of loop structures to impart flexibility/stretch together with the body (volume) and strength/stability.

They are kept lightweight and soft hand feel of the laminate by using fine bulked (texturized) filaments. It is expensive and hence used in high value garments like blazers and high fashion blouses.

#3. Non-woven interlinings

As the name implies there is no involvement of any yarn for interlacement to make the fabric.

It is made directly from fiber to fabric stage in the process reducing the cost of base fabric. As there is no yarn used in making nonwovens, it lacks in strength needed for apparel use and there are many techniques applied to impart required strength to nonwoven textiles, called Bonding. They are the most versatile product available from 10gsm to 200gsm and above, offering light, soft, flexible or strong for any application one can think of. The basic manufacturing technique is using mostly synthetic fibers to form a layer, which are imparted strength by bonding.

Let us understand the different layering and bonding methods, their use and their advantages and disadvantages.

Layering Method:

Different types of layering methods (spun laid, wet laid, dry/random laid, cross laid, and linear laying) are showing in the following images.

Bonding Method

Advantages and Disadvantages

HD-PE-ADHESIVE

| Advantages | Disadvantages |

| Good bond-strength on a wide range of fabics | No steam fusing capability |

| No reaction to steam no steam included strike-back | No high-frequency fusing capability |

| Good dry cleanability (A)* | Requires high fusing conditions |

| Excellent washability (950C), suitable for garment dyeing, etc. | Heavy contamination of taflon belts |

HD-PE-ADHESIVE

| Advantages | Disadvantages |

| Adequate bond-strength for small-area fusing | Hardening of the handle due to surface scatter coating |

| Low reaction to steam, low level of steam-included strike-back | No high-frequency fusing capability |

| Easy to fuse with hard-ires | Adhesive strike-through passible as this, lightweight outer fabrics |

| Adhesive weakened during dry cleaning can be reactivated by re-pressing | No dirt on roller/thread |

| Very good washability | Heavy contamination of taflon belts. |

PA-ADHESIVE

| Advantages | Disadvantages |

| Good bond-strength on a wide range of outer fabrics | Bond-strength sometimes inferior on sythetic outer fabrics and fabrics with special finishes |

| Melting point lowered by steam | Strong reaction to steam, possibly disadvantageous with low melt adhesives |

| Good dry cleanability to all solvents | Fendency to steam-included strike-back |

| Good washability (30-60 Degree C) | Washable only to 40C with MV adhesives |

| No contamination of teflon belts on continuous presses |

How to select the right interlining for my use?

To help decide on the type of interlining suitable for an application, one has to evaluate exact need, purpose, the material area of application, the care instruction and processing details of the garment.

The following FORMAT is suggested to be filled in and one may consult an interlining supplier to conduct a fusing test on the material, preferably on self-owned equipment in the factory and submit a test report for 5, 10 or 20 washes depending upon the brand value and price point of the garment.

Fusing Test Request

| Factory | |

| Address | |

| Production Head | |

| Quality Head | |

| Buyer/Country | |

| Style/Art | |

| Material | Content (100% polyester, georgette 50gsm, provide 1-2mtr original finished fabric) |

| Item | Ladies Blouse |

| Care Instruction | |

| Application area | Collar, neckband, placket, cuff |

| Fusing | Press model |

| Test Method | IS-1259 |

Fabric Sample

Based on the above information, the interlining manufacturer will submit the test results showing:

- Samples after fusing and after 5, 10 or 20 washes for appearance, hand feel reference

- Bond strength values after fusing and after washes. The buyer can decide if the results and looks are acceptable or not.

If left to choose, then one can decide based on:

- Appearance: no bubble or any surface unevenness after wash.

- No change in hand feel making it too hard.

- No change in visual looks: wavy moiré effect or colour change (please refer to picture NW 10). This is due to woven interlining or linear dot print pattern used in light open texture fabrics (see picture NW).

- No shiny dots of glue visible on another side.

- Normally for very light, transparent and flimsy fabric like georgette/chiffon colour of interlining must match the base colour and not use white/black/charcoal in general.

- For small area usage as mentioned which are close stitched from all sides the bond value of 5-7 N per 5cm strip is enough and safe.

| Do’s | Don’ts |

| Cut interlining in the same direction as shell | Don’t cut beyond pattern-5mm lesser |

| Put fusing on top of the shell facing down | Never shell on top of the shell |

| Ensure no folds in shell/fusing | No folds at output end in hot state |

| Check glue line temp by temp. Strip | Never lower /higher than given temperature. |

| Check the speed of machine before use | Never faster than the set speed-poor fuse |

| Check roller impression by carbon paper | No dirt on roller/thread |

| Check bonding before start | Don’t start feed w/o temp check |

About the Author: Rajkumar Rai is a Textile Graduate from Calcutta University and alumni of Indian Institute of Foreign Trade. He has over 36 years of work experience spanning in textile processing, apparel buying house, and other areas. He was India head of Freudenberg. He was heading a buying house over 25 years and worked with German buyers.

Image source: fusibleinterfacing.com