Innovations in Woven Interlining: What’s New in Textile Industry Trends?

The textile industry is rapidly evolving, with woven interlining at the forefront of innovation. This article explores the latest trends and technologies transforming woven interlining, a critical component that adds structure and stability to fabrics. It is used in a range of garments, including jackets, shirts, and skirts, to enhance the overall fit and durability. Traditional woven interlining fabrics have served their purpose well, but with ongoing advancements in technology, there are now exciting new developments that are revolutionizing the industry.

Table of Contents

- Understanding Woven Interlining

- Cutting-Edge Innovations in Woven Interlining

- Benefits of Modern Woven Interlining Technologies

- How Innovations in Woven Interlining Are Impacting the Textile Industry

- Future Trends in Woven Interlining

- Conclusion

Understanding Woven Interlining

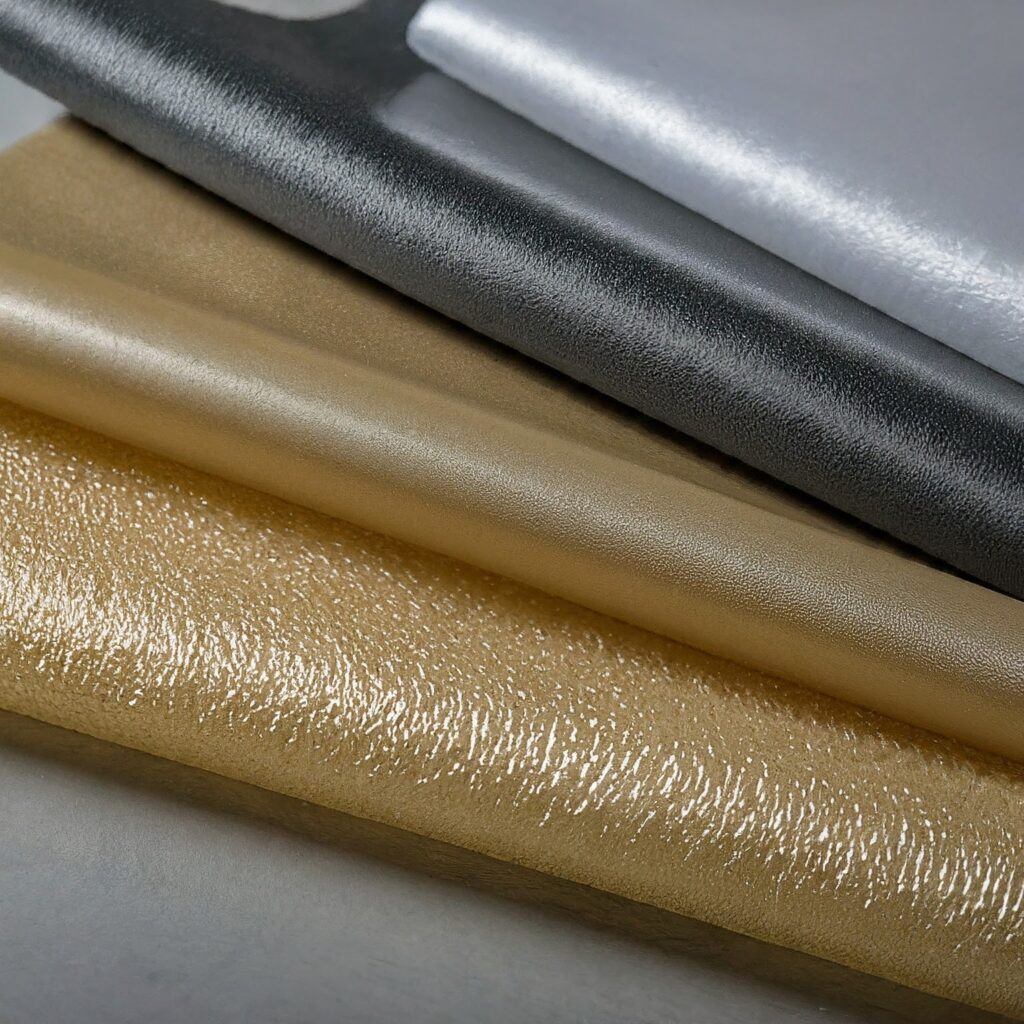

Before diving into the innovations, it’s important to have a basic understanding of woven interlining. It’s a fabric layer placed between the outer fabric and the lining of a garment. Woven interlining is typically made from various fibers, including cotton, polyester, and blends. It offers a range of properties, such as stiffness, drape, and breathability.

Cutting-Edge Innovations in Woven Interlining

As technology advances, so does the innovation in woven interlining. Here’s a look at some of the most notable trends and innovations currently shaping the textile industry:

- Smart Fabrics: One of the most exciting developments is the integration of smart fabrics with woven interlining. These fabrics can respond to environmental changes, such as temperature or humidity, providing enhanced comfort and functionality.

- Eco-Friendly Materials: Sustainability is a major focus in today’s textile industry. Innovations in interlining fabric now include eco-friendly materials, such as recycled fibers and organic cotton, which help reduce the environmental impact of textile production.

- Advanced Bonding Techniques: New bonding technologies are improving the adhesion between woven interlining and outer fabrics. Techniques like ultrasonic bonding and heat-sealing are creating more durable and flexible options, including non woven fusible interlining and woven fusible interlining.

- Customization and Personalization: Modern technology allows for greater customization of woven interlining. You can now find interlining in garments solutions that are tailored to specific fabric types, garment designs, and performance requirements.

- Enhanced Breathability and Flexibility: Innovations are also focusing on improving the breathability and flexibility of woven interlining. New materials and weaving techniques are designed to enhance airflow and movement, making garments more comfortable to wear.

Benefits of Modern Woven Interlining Technologies

The latest advancements in woven interlining offer several benefits that can enhance both garment quality and performance:

- Increased Durability: Improved bonding techniques and materials enhance the durability of woven interlining, ensuring that it maintains its shape and structure over time. This includes interlining fusible options that provide extra strength and stability.

- Enhanced Comfort: Smart fabrics and advanced weaving techniques contribute to better comfort by allowing garments to adapt to environmental conditions and provide a better fit. This includes advancements in lining and interlining fabric for improved wearability.

- Sustainability: Eco-friendly innovations are helping to reduce the environmental impact of textile production, making woven interlining a more sustainable choice. This includes the use of non woven interlining and recycled materials.

- Customization: The ability to customize woven interlining allows for better alignment with specific fabric requirements and garment designs, resulting in higher-quality finished products.

- Improved Performance: Enhanced breathability and flexibility contribute to better overall performance of the garments, making them more functional and comfortable. This is achieved through advanced techniques in fusing interlining and various interlining types.

How Innovations in Woven Interlining Are Impacting the Textile Industry

The impact of these innovations on the textile industry is substantial. Here’s how they are making waves:

- Elevating Garment Quality: The improved performance and durability of modern woven interlining are leading to higher-quality garments that last longer and maintain their appearance. This includes both woven interlining fabric and non woven interlining options.

- Meeting Consumer Demands: As consumers become more aware of sustainability and performance, textile manufacturers are responding with innovations that meet these demands, leading to increased market competitiveness.

- Driving Industry Growth: The advancements in woven interlining technology are fueling growth in the textile industry by opening up new opportunities for product development and differentiation.

- Encouraging Research and Development: The continuous innovation in woven interlining is encouraging further research and development, pushing the boundaries of what’s possible in fabric construction.

Future Trends in Woven Interlining

Looking ahead, here are some future trends to keep an eye on:

- Integration with Wearable Technology: As wearable technology becomes more prevalent, woven interlining may increasingly integrate with electronic components to create smart textiles with even more advanced features.

- Biodegradable Materials: The push for sustainability will likely lead to more innovations in biodegradable interlining fabrics, which can break down naturally and reduce environmental impact.

- Enhanced Functional Properties: Future developments may focus on adding new functional properties to woven interlining, such as improved water resistance or UV protection.

- 3D Printing and Customization: The use of 3D printing technology may allow for even greater customization of woven interlining, enabling on-demand production of tailored solutions.

Conclusion

The innovations in woven interlining are transforming the textile industry in exciting ways. From smart fabrics and eco-friendly materials to advanced bonding techniques and customization options, these advancements are enhancing garment quality, comfort, and sustainability.

As we move forward, embracing these innovations will be crucial for staying competitive in the textile market. Whether you’re a manufacturer, designer, or consumer, keeping up with the latest trends in woven interlining will ensure that you’re at the forefront of this dynamic industry.

Link of related Articles

- How Lightweight Interlining Enhances Woven Fabrics | Boost Performance

- How to Apply Woven Interlining for Optimal Results: Tips from the Experts

- Woven Interlining for Men’s Shirts & Suits | Enhance Garment Structure