All You Need to Know About Woven Interlinings

In textile manufacturing industries, interlining is a very common term. Interlining is nothing but binding two fabrics into a single unit that supports the manufactured piece of clothing. Depending on the outlook and usability of the manufactured item, the various woven interlining fabrics in use are cotton, silk, rayon, viscose, etc.

Know the concept

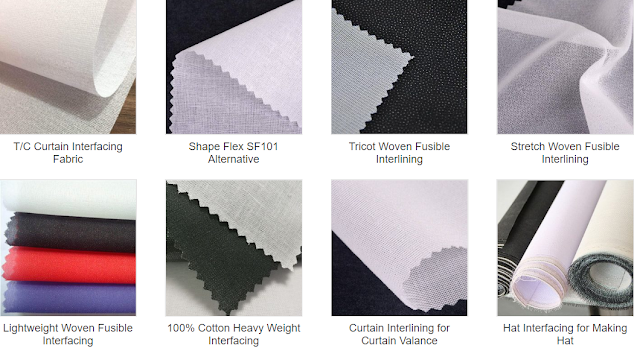

Fusion interlining has varied types of interlining processes, among which woven interlining is a variant. Here the underlining layer uses the materials made of 100% polyester woven fabric, blended materials or cotton made fabric. The materials in use are soft compared to the non-woven fabrics, and in most cases, they are also better in providing flexibility to the piece of apparel.

Key characteristics

The applications of woven interlining are more than non-woven for the various advantages of the texture of the used fabrics that brings better usability to the manufactured item. Using the woven fabric materials, you can make it malleable yet provide stability to the clothing. Go through the following to understand the properties better.

- Softer: The interlinings made of woven fabrics provide a soft feel to the piece of clothing that is not present with the non-woven ones. You will feel the softness, but at the same time, there is a stiffness to it that rightfully serves the purpose of the manufacturer. For this, it is more popular with apparel interlining for the sheer advantage of comfort and softness.

- Better stretch: As the fabric in use is a non-rigid one; it gives a better stretching advantage over the non-woven materials. The key feature of woven fabrics is better stretching under demanding conditions that increases comfort. It also helps in increasing the durability of the manufactured product in hindsight.

- Eco-friendly: Another reason behind the growing popularity of this type, especially in the fashion industries, is the capability of being environment friendly. Using cotton made fabrics and other naturally degradable materials help in making them nature friendly, unlike the non-woven ones with non-recyclable and artificial components.

- Lightweight: Interlinings made of woven fabrics are light in weight. For this, they are very popular in garment manufacturing, where they use this lining in various parts of the clothes without making them heavyweight. It can keep the manufactured item stiff and structured in a seamless way.

- Better bonding strength: The woven texture not only provides better flexibility but also generates better bond strength. The property of stretching of it helps in making the fusing bond stronger. It ensures lower risks of tearing and lesser damage as flexibility adds to the strength intake power of the manufactured item.

Using benefits

Interlining is a popular practice with garment manufacturers and those who require fabrics to develop other products like bags and luggage-making industries. In many cases, these work fields use woven fusion interlinings to make their product more durable and stable to damages. Look at the following to get an idea of the benefits of using it.

- Prevent creasing: Creases are a primary concern for the garment industries. Creased apparel is not attractive to look at and wear. For this, they use woven interlinings that help in preventing the outer crease of the cloth. Incorporating an extra layer inside helps maintain the rigidity of the outer fabric in the display. Woven materials being soft, also maintains comfort along with serving the purpose.

- Adding structure: In embroidery cases on the outer surface of the cloth or any manufactured object, it is better to have a stable structure underneath. Interlining helps in bringing a structure to the texture upon which any design properly fit. Also, in cases of delicate outer layers like organza or silk, it helps in adding a body with a firm layer inside.

- Adding density: By combining woven fabrics beneath the outer layer of clothing, it helps in bringing density to the entire apparel. Also, the fitting gets better when the garment has a better density that can sit right on the body. Many manufacturers also add extra layers or paddings that go inside the woven interlinings to hold better.

Summing up

Woven interlinings have distinct uses in the various work fields, and there are many ways to modify the used fabric. For providing better softness and malleability, woven interlinings are the best choice.